Products

HZS50 Stationary Concrete Batching Plant

-

Productivity: 50m3/h

-

Capacity of Mixer: 1.0m3

-

Discharge Height: 3.8m

-

Feeding Type: Skip Hopper

Description

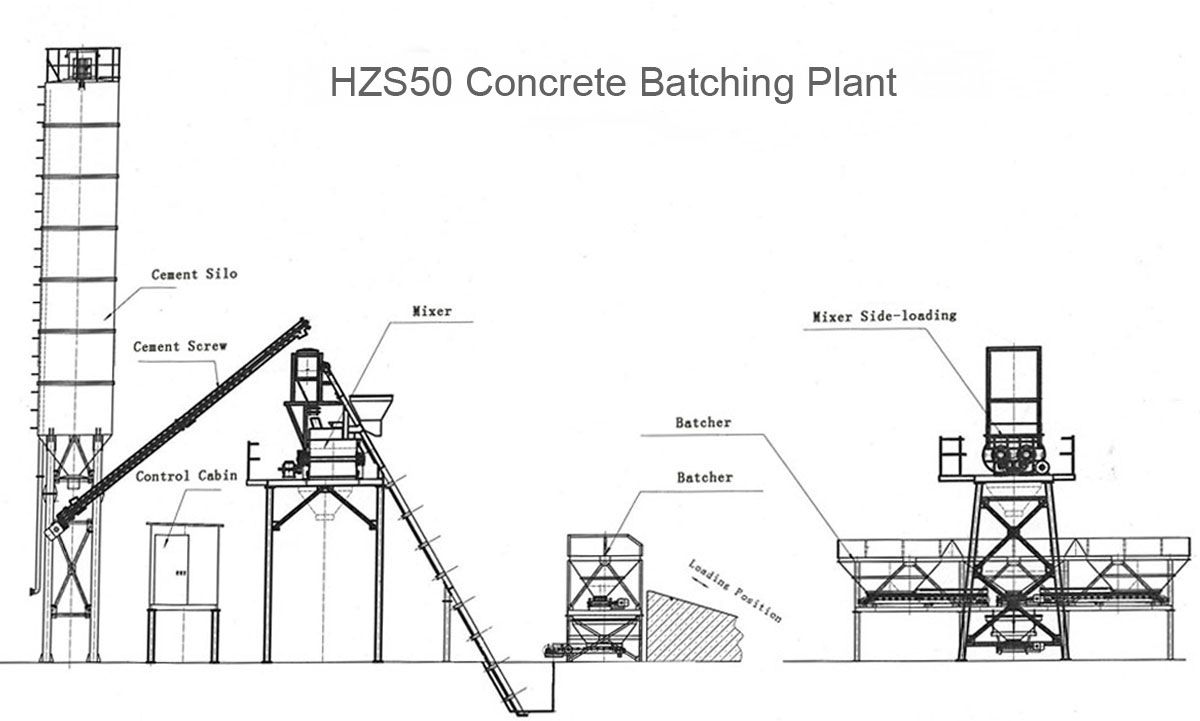

1. The Description of HZS50 Concrete Batching Plant:

(1). HZS50 series concrete batching plant(concrete mixing plant) belongs to compulsory and efficiency equipment, which can produce various kinds of concrete including quaking concrete and hard concrete.

(2). It is widely used small and medium scale building works, road and bridge works and concrete products prefabrication plants, as an ideal equipment to produce commercial used concrete.

(3). The main machine of this series use JS series double shaft compulsory concrete mixer, it can mix concrete evenly with a short period of mixing.

(4). It can be operated and maintained conveniently, through high technology control system with the newest design concept, for example: electric weighing, computer control, digital display, etc.

(5). The sand and stone feeding system use flat belt or herringbone belt, and equipped with maintenance sidewalk, which is the ideal selection for the construction units to produce high quality concrete.

2. The Introduction of HZS50 Concrete Batching Plant Components:

(1). HZS50 Concrete Batching Plant:

1.1. With high productive and long time wearing parts.

1.2. Electric weighing equipment with buffer device and auto compensation function.

1.3. International popular modular compact structure

1.4. Easy to install and remove and assembly

1.5. Adapt and apply the most advanced technologies around the world.

1.6. Excellent mixing performance

1.7. Main electrical components from Germany SIEMENS.

(2). JS1000 Concrete Mixer:

2.1. JS series concrete mixer with twin shaft compulsory concrete mixer

2.2. Not only work independently, also can work with PLD series aggregate batcher to make a simple concrete plant or adopted as the mixer in the high-end concrete batching plant.

(3). Cement Silo of HZS50 Concrete Batching Plant:

3.1. Steel cement silos are equipped with safety valve to balance the pressure inside and outside the silos.

3.2. It can be equipped level indicator so as to monitor the material level and amount.

3.3. With screw conveyor, the materials can be conveyed to a certain position.

3.4. Suitable for loading into containers and exporting

3.5. Perfect sealing assures its efficient working performance.

Specification

The Technical Parameters of HZS50 Concrete Batching Plant:

Model | HZS50 | |

Specification | Unit | Value |

Productivity | m3/h | 50 |

Capacity of Mixer | m3 | 1 |

Mixer Power | kw | 37 |

Discharge Height | m | 3.8(for customers choice) |

Aggregate Bin | Quantity | 3 |

Aggregate Bin Capacity | m3 | 1.6 |

Max. Weighing Value of aggregate | kg | 3000 |

Max. Weighing Value of cement | kg | 600 |

Max. Weighing Value of water | kg | 400 |

Max. Weighing Value of additive | kg | 50 |

Cement Silo | - | Optional |

Cement Screw Conveyor | - | Optional |

Control Mode | - | Auto/Semi control |

Drawing