News

Hot Products

Best concrete mixer

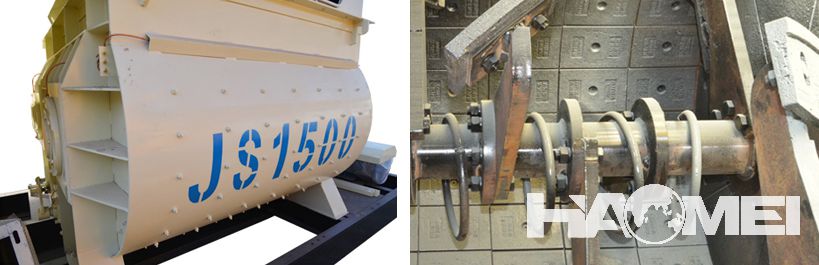

The JS series concrete mixer produced by Haomei Machinery has good mixing performance. The equipment adopts the spiral twin-shaft forced mixing main engine, which not only has strong mixer performance, but also can achieve good mixing effect for dry hard, plastic and various proportions of concrete.

Working principle of concrete mixer:

JS series mixer mixing system is composed of motor, pulley, reducer, open gear, mixing drum mixing device, water supply device. The motor drives the two-stage gear reducer through the belt, and the reducer end drives the two horizontally arranged stirring shafts to rotate at the same speed in the opposite direction through the split gear, so that the stirring arm and the stirring blade rotate. So as to achieve the stirring effect.

JS concrete mixer picture real shot

mixing system

1. The stirring device is composed of a main shaft, a stirring arm, a blade, a scraper, etc.

2. There are 7 stirring arms on the two mutually parallel main shafts of the stirring device. The two adjacent stirring arms on the same main shaft are distributed at 60°. The relative angle relationship between the two main shafts is fixed. This fixed relationship is determined by The coupling between the two reducers is guaranteed.

Feeding system

●The feeding system is composed of hoisting mechanism, feeding gantry, hopper, feeding nozzle and so on.

The brake motor drives the reel to rotate through the reducer, and the wire rope pulls the hopper through the pulley to climb along the track of the feeding rack. When climbing to the preset height, a pair of rollers on the bucket door at the bottom of the hopper enters the water track of the loading rack, and the bucket door opens automatically. , the material is put into the mixing drum through the feeding nozzle.

Unloading system

●The unloading system is composed of unloading door, air pump, reversing valve, air distribution valve, cylinder, electrical and other mechanisms.

●The discharge door is at the bottom of the mixer, the pneumatic discharge and the opening and closing position of the discharge door are controlled by the cylinder, and the sealing of the discharge door can be ensured by adjusting the position of the sealing strip.

●JS1500 mixer unloading manual operation lever is used for emergency unloading during temporary power failure and unloading when the cylinder fails. It should be removed at ordinary times to prevent injury.

electrical control system

●The electrical circuit of JS1500 mixer has air switch, fuse, thermal relay, and has functions of short circuit protection and overload protection.

●The control button, air switch handle and indicator light are all on the distribution box door, and there is a door lock. There are protective covers on the buttons.

Haomei Machinery specializes in the production of concrete mixing equipment. The JS series concrete mixer models produced include JS500, JS750, JS1000, JS1500, JS2000, JS3000, etc., with a complete range of models to meet the different output needs of customers. The company's products are exported to many overseas countries with favorable prices. Users can visit the factory to order.