Products

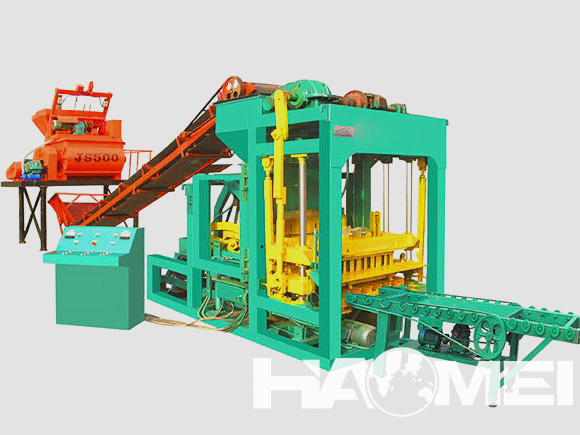

QT8-15 Automatic Brick Making Machine

-

Model: QT8-15 series

-

Molding cycle: 15-20S

-

Capacity: 720-2160Pcs/Hr

-

Power: 20-48kw

Description

The automatic brick making machine produced by Haomei are of high quality and long service life, the automatic block machine save labor cost much.Moreover, a concrete brick machine can produce a variety of different specifications of bricks by various molds. The raw materials can be industrial waste residue, construction waste, fly ash waste and so on. Hollow brick making machine can produce a variety of specifications bricks, such as scale brick, hollow brick, porous brick, concrete bricks and so on.

Features of Haomei Automatic block making machine:

1. Reliability. The machine frame is made of super- strength steel and by special welding technology, the imported elements are applied widely, so that the stability and reliability of the machine in long term running are insured.

2. The whole process uses a PLC aptitude control and dialogue system of human-machine interface, easy to analyze the chance signal, fault diagnosis and parameters setting, ensure the best operation effect of the fully automatic brick making machine.

3. Unique design. The special loading and supply unit, the multi-line whipping forks are fixed at inside of material feed box. The whipping forks works and feed the material to mold box forcedly during the material feed box moves to up of mold box, the feed will smoothly and equalization, than for the product, the intensity is insured and the weight is equal.

4. Design with super strong vibrating activated force, The computer controls the pressure and flowing rate of hydraulic system; vertical synchrony-vibration; frequency conversion; brake, final the product reaches the high density and high strength within short time.

5. Multi use; strong performance; the many kind of products with difference form and size can be made when use the difference mold, such as wall block, honeycomb type block, road block and slope block.

Specification

The Parameters of QT8-15 Automatic Brick Making Machine:

| QT8-15 Automatic Brick Making Machine | |

| Specificatio | Value |

| Modle | QT8-15 |

| Molding Cycle(s) | 15-20 |

| Pallet Size(mm) | 970x680x40 |

| Installed Capacity(kw) | 33.55 |

| Weight(t) | 10 |

| Machine Dimensions(mm) | 4750x2000x2950 |

| The Highest Frequency(r/min) | 4800-2100 |

| Brick/Block Size | 9" x 4" x3",10" x 5" x3",8" x 4" x4" |

| Brick Raw Material | Cement, Fly Ash, Sand, Stone Dust, Gysum, Lime Sludge,etc |

| Usage/Application | For Making,Fly ash bricks,Concrete Blocks,Paver Blocks,Solid Blocks, Cement Blocks, Hollow Blocks |

| No. Of Bricks Per Stroke | 4, 6, 8, 10,12, 14, 16 Pcs |

| Pallets Size | 22" x 23" x 19mm (Thickness) |

| Automation Grade | Semi or Fully Automatic |

| Brick/Block Type | Solid, Interlock, Hollow, Paver |

| Method | Hydraulic Pressure |

| System | PLC Controlled |

| Capacity(Blocks/Bricks ) | 1000-4000 pcs per hour |

| Capacity per 8 Hours | 6000pcs to 40000 pcs |

| Voltage | 440 Volt |

| Space Required | 30 ft ( L) x 25 ft (W) x 16 Ft (H) |

| Total Power Required | 22 HP to 50 HP |

| Material | Mild Steel |

| Accessories | Main Press Machine with Vibrator System, Rollers Pan Mixture, Belt Conveyor, Bearing Conveyor, Electronic Control Panel, Hydraulic Power Pack, Material Trolley, Hydraulic Pallets trolley. |

| Treatment Time of Bricks/Blocks | Minimum of 7- 8 Days |

Theoretical yield table:

| Product Name | Product Specifications(mm) | Number Per Plate(Block) | Block/Hour | Blok/8 Hours |

| Block | 390x190x190 | 8 | 1920-1440 | 15360-11520 |

| Brick | 240x115x90 | 22 | 5040-3780 | 40320-30240 |

| Standard Bricks | 240x115x53 | 45 | 10080-7560 | 80640-60480 |

Note: The above theory of output data, depending on the operating proficiency may be biased.