News

Hot Products

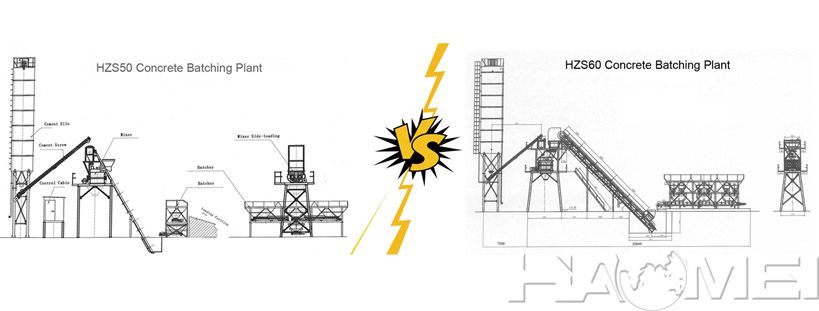

Differences between HZS50 and HZS60 concrete batching plants

HZS50 and HZS60 concrete batching plants are both medium-sized models of engineering or commercial concrete mixing equipment. Both are widely welcomed by customers in practical applications. The main differences between them are reflected in the following aspects:

1. Configuration and model

Mixer host: Both HZS50 and HZS60 concrete batching plants are equipped with JS1000 forced mixers. However, the mixer host of HZS60 concrete mixing plant is clearly JS1000 twin-shaft forced mixer, which may be more outstanding in mixing efficiency and performance.

Batching machine: Both are equipped with PLD1600 batching machine, but the batching machine of HZS60 concrete mixing plant adopts pneumatic weighing, while HZS50 mixing plant may adopt pneumatic single weighing or other weighing methods. Pneumatic weighing usually has higher weighing accuracy and efficiency.

2. Loading method

HZS50 mixing plant: Loading method using lifting hopper. This feeding method can efficiently transport and dump aggregates while reducing the floor space through the unique design of the hopper and track.

HZS60 Mixing Plant: Use belt feeding. The belt conveyor can continuously transport aggregates to the mixing host, with the advantages of high efficiency and low failure rate. However, this method will occupy a relatively large area.

3. Floor Space

The HZS50 mixing plant uses a wire rope to pull the hopper for feeding, which occupies a relatively small area, which is conducive to installation and use in limited space. However, the HZS60 mixing plant uses a belt feeding method and is equipped with additional facilities such as waiting silos, so the floor space will be relatively large.

4. Application Field

HZS50: Suitable for small and medium-sized construction projects, such as rural road construction, house construction, etc.

HZS60: Suitable for medium-sized construction projects, such as highways, bridges, etc., which can meet higher production needs.

5. Cost

HZS50: Due to low output and small equipment scale, the cost is relatively low.

HZS60: Due to the large production capacity and high equipment requirements, the initial investment and maintenance costs are higher.

Therefore, when choosing a concrete mixing plant, you need to choose a model that suits you according to the specific project requirements.

HAOMEI Machinery specializes in the production of concrete batching plants, with a full range of product models, stable quality, export overseas, factory direct sales, preferential prices, and guaranteed after-sales service.