Products

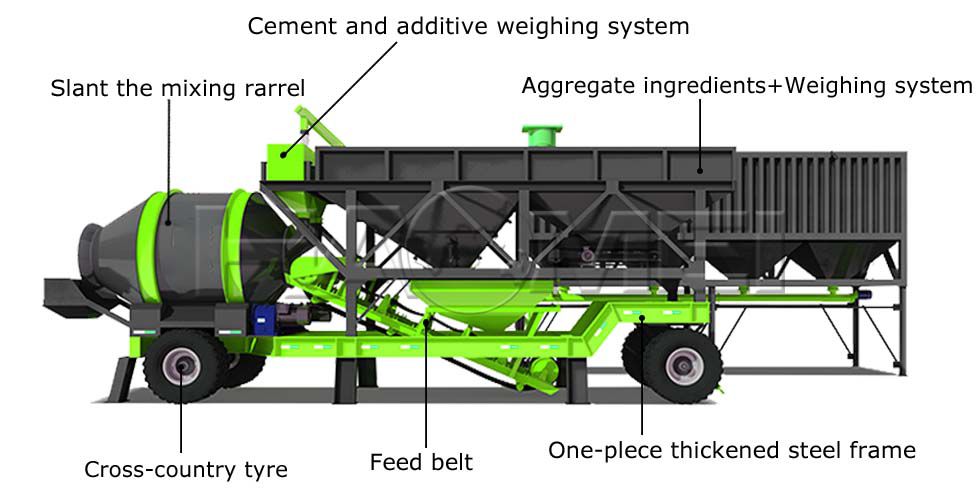

YHZM25 Mobile Concrete Mixing Station

-

25m³/h: 25m³/h

-

Concrete mixer: JZM500

-

Cycle time: 1.5 minutes

Description

YHZM25 Mobile Mixing Station is a new trailer-type mobile cement concrete mixing station with a novel and unique structure. It integrates aggregate, weighing, mixing, conveying and other operations in one trailer unit. It has the characteristics of simple and clear human-machine interface, stable and reliable operation and strong overall mobility. It is an ideal model for mobile construction of highways, bridges, ports, hydropower and other projects.

Features of JZM500 Two-Storage Mobile Concrete Mixing Station:

Easy to move: The equipment is installed on a trailer chassis, which is convenient for transportation and movement, and is suitable for projects with frequent site changes.

Quick installation: The equipment has a compact structure, small footprint, and can be quickly installed and disassembled without complex foundation construction.

Easy operation: Equipped with a fully automated control system, it is easy to operate and improves construction efficiency.

Good environmental protection: It is generally equipped with a dustproof device, which meets environmental protection standards and reduces dust pollution at the construction site.

Application scenarios:

YHZM25 mobile mixing station is widely used in:

Temporary road construction

Water conservancy projects

Small residential construction

Construction in rural and remote areas

This type of mixing station is an ideal choice for many small and medium-sized projects due to its small size, flexibility, easy installation and moderate production capacity.

Detailed

Specification

General Parameters

Model | YHZM25 | |

Capacity | 25m3/h | |

Concrete mixer | JZM500 | |

Cycle time | 1.5 minutes | |

Weighing accuracy | Aggregate | ±2% |

Cement | ±1% | |

Water | ±1% | |

Water | ±1% | |

Detailed specification

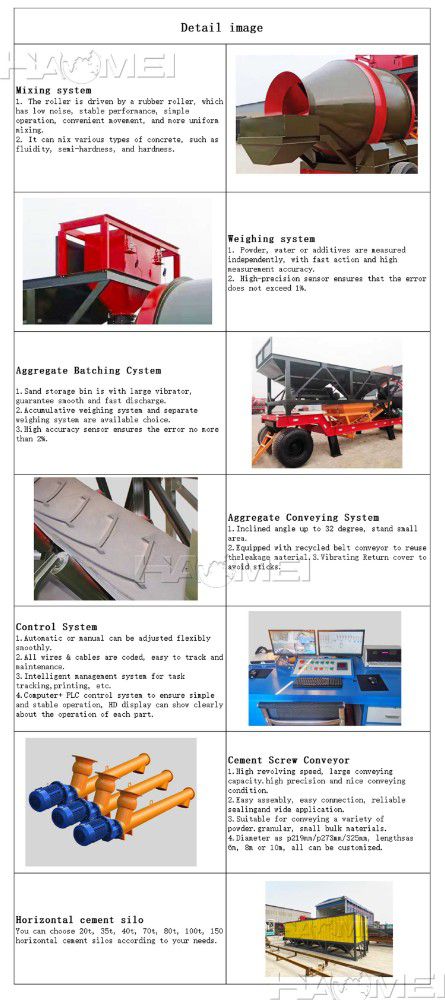

1. Concrete mixer

Name | Specification |

Model | JZM500 drum mixer |

Capacity | 0.5m3/batch |

Motor power | 4.5kw*2 |

Mixing time | 40s |

Discharging height | 1300mm; If using concrete transit mixer to collect concrete,we can make a slope with the height of 3000mm to enable it to collect concrete. |

2. Aggregate batcher

Name | Specification |

Model | PLD800 |

Volume of storage bin | 3.4m3*2pcs |

Weighing sensor | 1000kg*3pcs |

Cylinder | 100*250*1pcs |

Motor power | 4kw*2pcs |

| Belt conveyor size | 500*3300mm*1 ,600*5880mm*1 |

Loading height | 2910mm |

Thickness of storage bin steel plate | 3mm |

3.Scales

Name | Specification | |

Cement scale | Volume of cement storage bin | 0.3m3 |

Weighing accuracy | +/-1% | |

Sensor | 500kg*3pcs | |

Water scale | Volume of water storage bin | 0.15m3 |

Weighing accuracy | +/-1% | |

Sensor | 300kg*3 | |

Water pump power | 1.5kw | |

Additive scale | Volume of additive storage bin | 0.03m3 |

Weighing accuracy | +/-1% | |

Sensor | 50kg*1 | |

Additive pump power | 50kg*1 | |

4.Chassis

Name | Specification |

Qty. | 1 pcs |

Size | 11100mm*2000mm*780mm |

Tyre model | 1000mm |

5.Control system

Name | Specification |

Electrical elements brand | CHNT / DELIXI |

Control console |