News

Hot Products

360-Degree Rotating Self-Loading Concrete Mixer

The self-loading concrete mixer is a highly efficient device that combines the functions of a concrete mixer truck and a cement mixer. It can automatically complete a series of operations, including feeding, measuring, mixing, and discharging. Equipped with a powerful engine and a four-wheel steering system, it is flexible and easy to operate. The driver can handle it like a small car, effortlessly driving the equipment to the desired location on the construction site.

This mixer features exceptional automatic loading capabilities, allowing rapid loading of raw materials such as cement, aggregates, and stones. Even when the materials are scattered throughout the construction site, it can handle the situation with ease. With this equipment, there is no need to worry about material transportation and unloading, significantly enhancing construction efficiency and productivity.

360-Degree Rotation Features

1. 360-Degree Rotating Mixing Drum

The mixing drum of the self-feeding concrete mixer truck usually supports 360-degree rotation, ensuring uniform mixing of concrete during transportation and preventing solidification or stratification.

The rotating function also facilitates precise control of the concrete pouring position and speed during unloading, greatly improving construction efficiency.

2. 360-Degree Panoramic Imaging System

Modern mixer trucks are commonly equipped with a 360-degree panoramic imaging system that utilizes multiple high-definition cameras to achieve blind-spot-free monitoring. This helps the driver stay aware of the surroundings in real time.

The system, combined with AI algorithms, can recognize potential hazards such as pedestrians and vehicles, issuing warnings to significantly reduce the risk of accidents.

3. 360-Degree Rotating Robotic Arm or Loading Device

The robotic arm or loading device can perform 360-degree rotation in both horizontal and vertical directions.

Enhanced Material Loading Flexibility: Adapts to multi-angle material acquisition.

Reduced Equipment Movement Frequency: Increases work efficiency.

4. 360-Degree Rotating Cab

Some mixer trucks are equipped with fully enclosed luxury cabs that support 360-degree rotation, allowing the driver to observe the surroundings comprehensively and enhancing operational flexibility and safety.

This design is particularly suitable for narrow or complex construction sites, allowing the driver to adjust the viewing angle and eliminate blind spots.

Advantages of Self-Loading Concrete Mixer Truck

1.Efficient Construction: The self-loading design reduces material loading time, while the 360-degree rotating mixing drum maintains concrete uniformity, significantly boosting construction efficiency.

2.Labor Cost Savings: Automatic loading and intelligent operation systems reduce manual intervention, lowering labor costs.

3.Reduced Material Loss: The rotating mixing technology effectively prevents concrete segregation and stratification, ensuring casting quality.

4.Eco-Friendly and Energy-Saving: The equipment has low energy consumption, reducing carbon emissions and aligning with green construction concepts.

HAOMEI Machinery's latest self-loading concrete mixer trucks include models with capacities of 1.2 CBM, 1.8 CBM, 2.6 CBM, 3.5 CBM, 4.0 CBM, 5.5 CBM, and 6.5 CBM, meeting the needs of various engineering projects.

Application Scenarios

Urban Infrastructure Construction: Such as bridge and tunnel projects.

Rural Road Construction and Maintenance.

Small Construction Sites and On-Site Concrete Production.

Concrete Transportation in Mountainous and Hilly Areas.

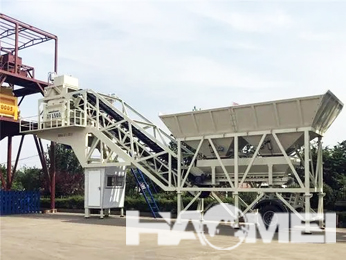

Relying on technological innovation, HAOMEI optimizes product structures. The company currently offers a wide range of concrete machinery products, including JZC series concrete mixers, JS series concrete mixers, PLD concrete batching machines, HZS series concrete mixing plants, mobile concrete mixing plants, concrete pumps, and self-loading concrete mixer trucks.