News

Hot Products

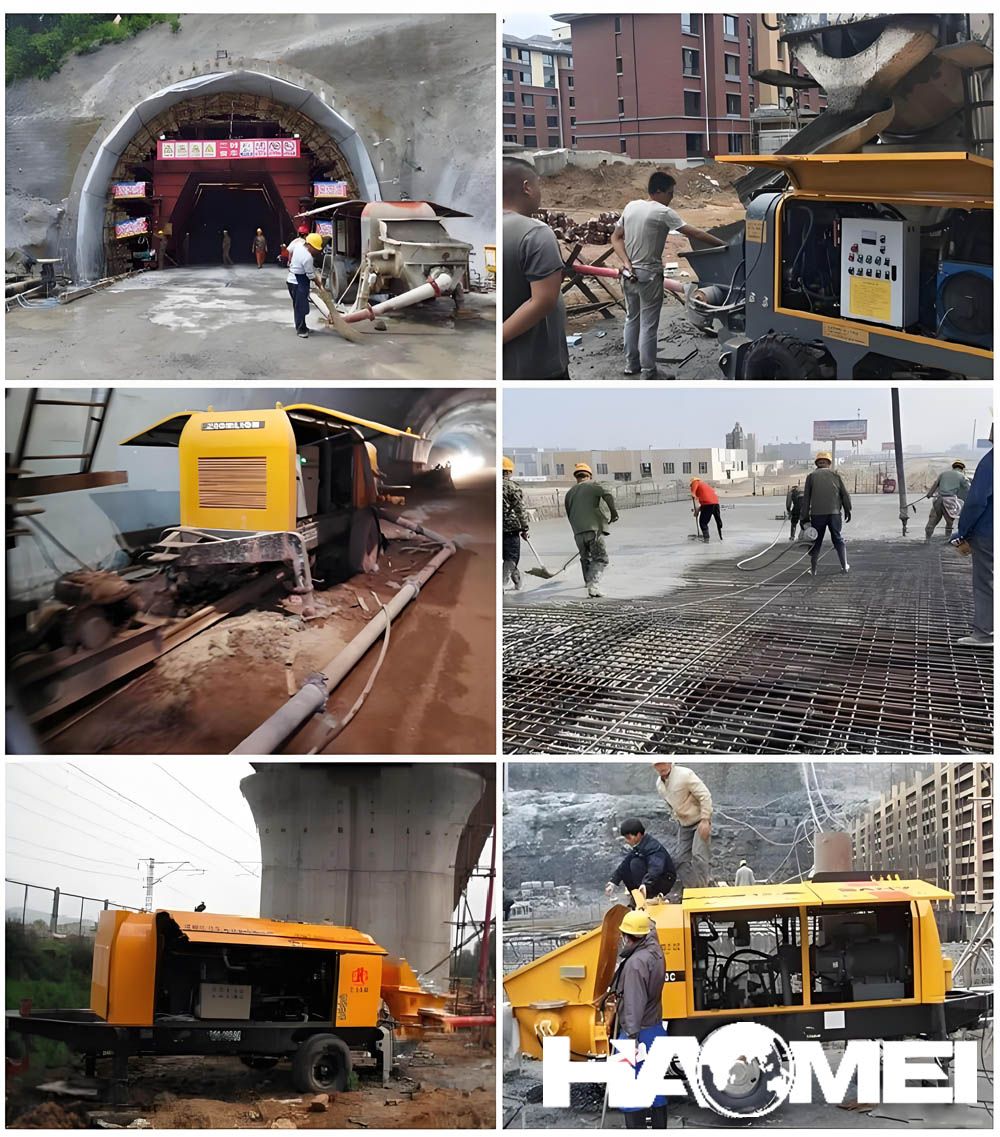

HBT series trailer concrete pumps are widely used

HAOMEI Machinery, an experienced manufacturer of concrete conveying equipment, mainly produces various electric or diesel trailer concrete pumps with a conveying capacity of 15-120 m³/h and a maximum pressure of 5-20 MPa.

The HBT series trailer concrete pump, also known as a towable concrete pump, is a type of engineering machinery designed to transport concrete through pipelines to designated locations. Its trailer-style design allows for flexible mobility between different construction sites, making it suitable for projects of various scales. As a high-efficiency concrete conveying device, the HBT series is widely applied in urban construction, bridge projects, power and energy facilities, and other construction fields.

Compared with traditional manual or mechanical lifting methods, the HBT series concrete pump can significantly improve construction efficiency, reduce labor costs, minimize material waste, and enhance the quality of concrete placement, making it an indispensable piece of equipment on modern construction sites.

HAOMEI Machinery provides HBT60-HBT90 models of trailer concrete pumps, with a maximum horizontal conveying distance of up to 1400 m and a vertical distance of up to 320 m. These pumps can handle concrete with aggregate sizes up to 50 mm, suitable for different concrete mixes.

Structure and Working Principle of Trailer Concrete Pumps

The HBT series trailer concrete pump consists of the main hydraulic pump system, hydraulic control system, S-valve switching system, hopper mixing system, electrical control system, and trailer chassis system.

The basic working principle is as follows:

1. Hydraulic oil drives the main cylinder, causing the piston in the concrete cylinder to move back and forth;

2. While the left cylinder draws in concrete, the right cylinder pushes concrete into the pipeline through the S-valve;

3. The switching action of the S-valve is controlled by the hydraulic system, achieving continuous and stable concrete pumping;

4. The entire process is precisely regulated by a PLC control system, ensuring high efficiency and smooth operation.

This design achieves continuous pumping, low pulsation, and low noise, suitable for different concrete strength grades and various construction conditions.

Wide Range of Applications

Urban Construction

Efficient concrete pumping is crucial in urban building projects. The high pumping capacity of the HBT series ensures faster construction progress and shorter project schedules. Even on confined city sites, HBT pumps can deliver concrete smoothly, ensuring that project timelines are not affected.

Transportation Infrastructure

(1) Bridge Construction: Its flexibility allows it to easily handle complex construction environments.

(2) Tunnel Projects: Some tunnel construction projects reported a 30% increase in efficiency after using the HBT series.

(3) High-Speed Rail Construction: Meets the strict quality and continuous pouring requirements of high-speed railway projects.

Large-Scale Specialized Projects

Water Conservancy Projects: Such as dams and reservoirs that require continuous large-volume concrete pouring.

Energy Projects: Power plants and energy facilities that demand high-quality concrete.

Why Choose the HBT Series Trailer Concrete Pump?

High Efficiency: Advanced hydraulic technology enables rapid concrete pumping, saving substantial time.

High Reliability: Key components are imported, ensuring stable operation in harsh construction environments.

Cost-Effectiveness: Compared to traditional concrete placement methods, HBT series trailer pumps shorten project schedules and reduce labor costs.

Easy Operation & Maintenance: Modular design of critical components allows easy disassembly and maintenance.