News

Hot Products

LB1500 Asphalt Mixing Plant Capacity 120 tph

In modern highway construction, municipal engineering, and large-scale infrastructure projects, the asphalt mixing plant is a core production facility. Its performance and efficiency directly affect project quality, cost, and construction schedule. With a stable and reliable designed capacity of 120 tons per hour, the LB1500 asphalt mixing plant has become an ideal choice for many medium- to large-scale projects.

The LB1500 is a medium-capacity asphalt mixing plant with a maximum output of 120 tph. Featuring advanced mixing technology and an optimized structural design, it can efficiently produce various grades of asphalt mixtures to meet the requirements of highways, urban roads, airport runways, and other large infrastructure projects.

In actual operation, the LB1500 mixing plant ensures stable material feeding while maintaining precise mix proportion control. It is suitable for producing AC, SMA, OGFC, and other types of asphalt mixtures.

Core Design Advantages

1.Drying System

Equipped with a high-efficiency counterflow drying drum and an optimized burner design, the system ensures uniform aggregate heating with lower energy consumption, providing stable temperature conditions for subsequent mixing.

2.Vibrating Screening System

A multi-layer precision vibrating screen enables fast and accurate aggregate classification, ensuring that the gradation of the asphalt mixture meets design specifications.

3.Twin-Shaft Forced Mixing Unit

The scientifically designed mixing arm angles and arrangement allow asphalt and aggregates to be uniformly coated within a short time, resulting in high mixing efficiency and low residual content.

4.Environmental Protection Design

Integrated baghouse dust collector and exhaust gas recovery systems effectively control dust and emissions, meeting increasingly stringent environmental construction standards.

5.Intelligent Control System

PLC + industrial computer automatic control system with functions such as recipe storage, fault diagnosis, and production data traceability significantly reduces operational complexity and human error.

Why Choose an LB Asphalt Mixing Plant?

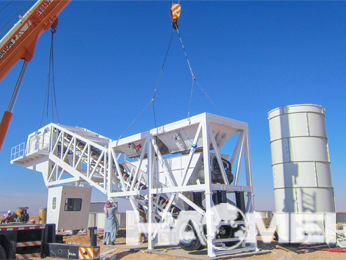

1. Modular Design for Fast Installation

The entire plant adopts a containerized modular design, with major components pre-assembled at the factory. On-site installation is fast, greatly reducing relocation time and cost for road construction projects that require frequent site changes.

2. Intelligent Control System

Equipped with a fully automatic PLC control system and dual-computer hot standby interface, operators can monitor real-time sensor data. One-click production reports enable digital and transparent project management.

3. Excellent Stability and Durability

Key components such as mixing arms, liners, and paddles are made of highly wear-resistant alloy materials, ensuring long service life and reducing downtime caused by maintenance.

4. Wide Applicability

Whether producing conventional asphalt mixtures, modified asphalt mixtures, or fiber-reinforced special mixtures, the LB1500 can handle all requirements through flexible parameter adjustment.

5. Energy-Saving and Cost-Effective Operation

Through optimized thermal efficiency, matched power systems, and intelligent temperature control technology, the LB1500 achieves leading fuel and power consumption performance in its class, significantly reducing long-term operating costs.

6. Superior Finished Mix Quality

From cold aggregate proportioning to final discharge, the entire process is precisely controlled. Key indicators such as asphalt–aggregate ratio, temperature consistency, and gradation stability perform exceptionally well, laying a solid foundation for high-quality pavement construction.

Application Fields

Highway Construction and Expansion

Especially suitable for new construction and upgrading of secondary highways and provincial roads.Urban Municipal Roads

Meets the high environmental and quality requirements for urban main roads and bridge paving projects.Special Facilities such as Airports and Ports

Suitable for apron areas, container yards, and other sites requiring thick-layer asphalt paving.Large-Scale Maintenance Projects

Ideal for sectional highway maintenance and major rehabilitation of national and provincial roads requiring continuous material supply.

HAOMEI Machinery offers a full range of asphalt mixing plants, including LB800, LB1000, LB1500, and LB2000, to meet different production capacity requirements. With advantages such as environmental performance, intelligent operation, and reliable structure, HAOMEI products are exported to more than 40 countries and regions worldwide. Factory-direct supply, competitive pricing, and reliable after-sales service are guaranteed.