News

Hot Products

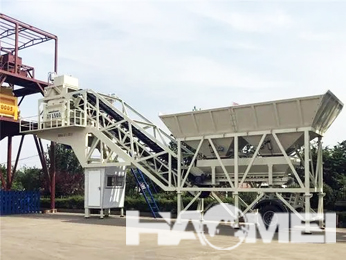

Maintenance and maintenance of concrete mixing station

The concrete mixing plant is an important equipment for producing concrete. Its maintenance can extend the service life of the mixing station, improve production efficiency and reduce equipment failure rate. Concrete mixing station manufacturers introduce to you how to maintain the mixing station and extend its service life.

1. At the end of winter work, drain all the residual water and additives in the water pump, additive pump, water tank, and additive tank to prevent damage.

2. After the work is completed, keep the mixing station clean and clean dust and cement regularly to avoid clogging or damaging the equipment.

3. Regularly check the oil quantity and quality of the lubrication system, and replace the lubricating oil according to usage to ensure normal lubrication of the equipment.

4. Check the wear of blades, scrapers, mixing arms, etc., and adjust the clearance or replace if necessary.

5. Check whether the connecting bolts of the vibrator are loose.

6. Check the quality of the lubricating oil in the crankcase of the air compressor and replace it if necessary.

7. Check whether the contactor and the static and dynamic contacts of the intermediate relay in the electrical appliance are damaged or burned out.