News

Hot Products

Fully automatic fly ash brick making machine

Haomei Machinery's fully automatic fly ash brick making machine adopts a PLC intelligent control system and uses fly ash as raw material to automatically produce fly ash bricks. This machine has a computer control system, so it has the advantages of high automation and high efficiency. It is very suitable for large and medium-sized projects and is widely used in urban construction, municipal engineering, real estate, water conservancy projects, high-speed railway and other industries.

The vibration pressing forming device of the fly ash brick making machine consists of a frame body, a unique vibration excitation device, a vibration isolation device, a pressurizing device and a demoulding device. It has the functions of automatic raw material weighing, automatic mixing, batching plant, silo, discharge of finished bricks through conveyor and other functions for rapid production.

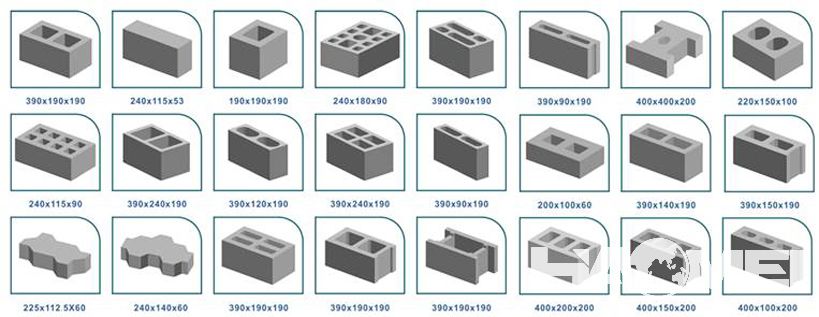

The fly ash brick machine is mainly QT series, including QT4-15, QT6-15, QT8-15, QT10-15 and other models, which can produce bricks of different shapes, such as hollow bricks, interlocking bricks, solid bricks, But only if you have a lot of molds.

Advantages of fully automatic fly ash brick making machine:

1. Powerful vibration system. Ensure that high-strength finished fly ash bricks can be produced.

2. PLC touch control system. It is easy to operate, runs smoothly and has a low failure rate.

3. There are many varieties of finished fly ash bricks, and bricks of various shapes can be obtained by simply changing the mold.

4. The molding cycle is short and efficient, each molding cycle is 13 to 20 seconds.

5. Frequency conversion energy saving. Greatly save electricity and extend the service life of the motor.

6. The fully automatic fly ash brick making machine has low noise and long service life. The vibration system is equipped with an air cushion device.