Products

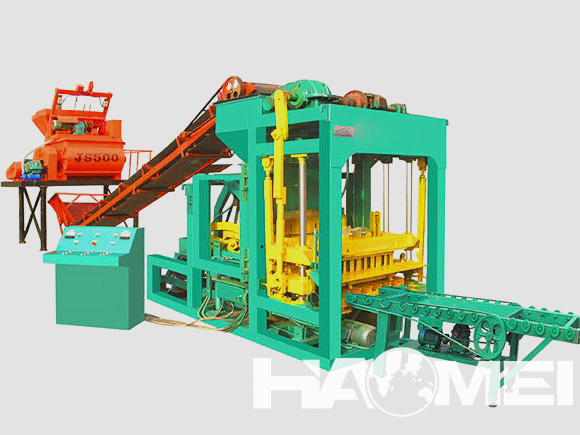

QT6-15 Paver Block Machine

-

Model: QT6-15

-

Molding cycle: 15-20S

-

Capacity: 1440Pcs/Hr

-

Power: 29kw

Description

Haomei paver block machine could complete mass production of almost kinds of paver bricks, pavement bricks and blocks. QT6-15 paver block making machine for sale could achieve many special and nonstandard concrete blocks in form of multilevel production, which can not be produced by single pallet equipment. Haomei bricks machine has huge advantages of multilevel production. Moreover the wet bricks can proceed maintenance directly. In this way, it could reduce many working so that save a lot of time and cost.

Features of QT6-15 Paver Block Machine:

1.The new technology support, vibrational force can meet the production of high-strength bearing block and non-load-bearing blocks.

2.Use QT6-15 shaper, with layered fabric body, either can be used as QT6-15, produce blocks and bricks, but also produce smooth surface or colored bricks, the road brick, tile and water grass slope brick after increasing layered fabric machine.

3.The body’s use of advanced welding technology, the use of high-strength steel and special materials, strong resistance to vibration.

4.Exciting and full sync integration platform vibration mode, tap the machine to achieve the best results.

5.Multi-pole oriented approach and exceptional wear-resistant materials to ensure the die and punch accuracy of movement.

6.Using a special fast fabric device to forming fabrics fast, smooth, uniform, in place.

7.Using fork rotary feeding system, block the production of various materials have good adaptability.

Specification

| QT6-15 Paver Block Machine | |

| Specification | Value |

| Modle | QT6-15 Paver Block Machine |

Molding Cycle(s) | 15-20 |

Pallet Size(mm) | 970x680x30 |

Installed Capacity(kw) | 29.00 |

Weight(t) | 9.5 |

Machine Dimensions(mm) | 6350x1680x2850 |

The Highest Frequency(r/min) | 4800-5100 |

| Brick/Block Size | 9" x 4" x3",10" x 5" x3",8" x 4" x4" |

| Brick Raw Material | Cement, Fly Ash, Sand, Stone Dust, Gysum, Lime Sludge,etc |

| Usage/Application | For Making,Fly ash bricks,Concrete Blocks,Paver Blocks,Solid Blocks, Cement Blocks, Hollow Blocks |

| No. Of Bricks Per Stroke | 4, 6, 8, 10,12, 14, 16 Pcs |

| Pallets Size | 22" x 23" x 19mm (Thickness) |

| Automation Grade | Semi or Fully Automatic |

| Brick/Block Type | Solid, Interlock, Hollow, Paver |

| Method | Hydraulic Pressure |

| System | PLC Controlled |

| Capacity(Blocks/Bricks ) | 1000-4000 pcs per hour |

| Capacity per 8 Hours | 6000pcs to 40000 pcs |

| Voltage | 440 Volt |

| Space Required | 30 ft ( L) x 25 ft (W) x 16 Ft (H) |

| Total Power Required | 22 HP to 50 HP |

| Material | Mild Steel |

| Accessories | Main Press Machine with Vibrator System, Rollers Pan Mixture, Belt Conveyor, Bearing Conveyor, Electronic Control Panel, Hydraulic Power Pack, Material Trolley, Hydraulic Pallets trolley. |

| Treatment Time of Bricks/Blocks | Minimum of 7- 8 Days |

Theoretical yield table:

Product Name | Product Specifications(mm) | Number Per Plate(Block) | Block/Hour | Blok/8 Hours |

Block | 390*190*190 | 6 | 1080 | 8640 |

Brick | 240*115*90 | 15 | 2700 | 21600 |

Standard Bricks | 240*115*53 | 30 | 5940 | 47520 |

Note: The above theory of output data, depending on the operating proficiency may be biased.