News

Hot Products

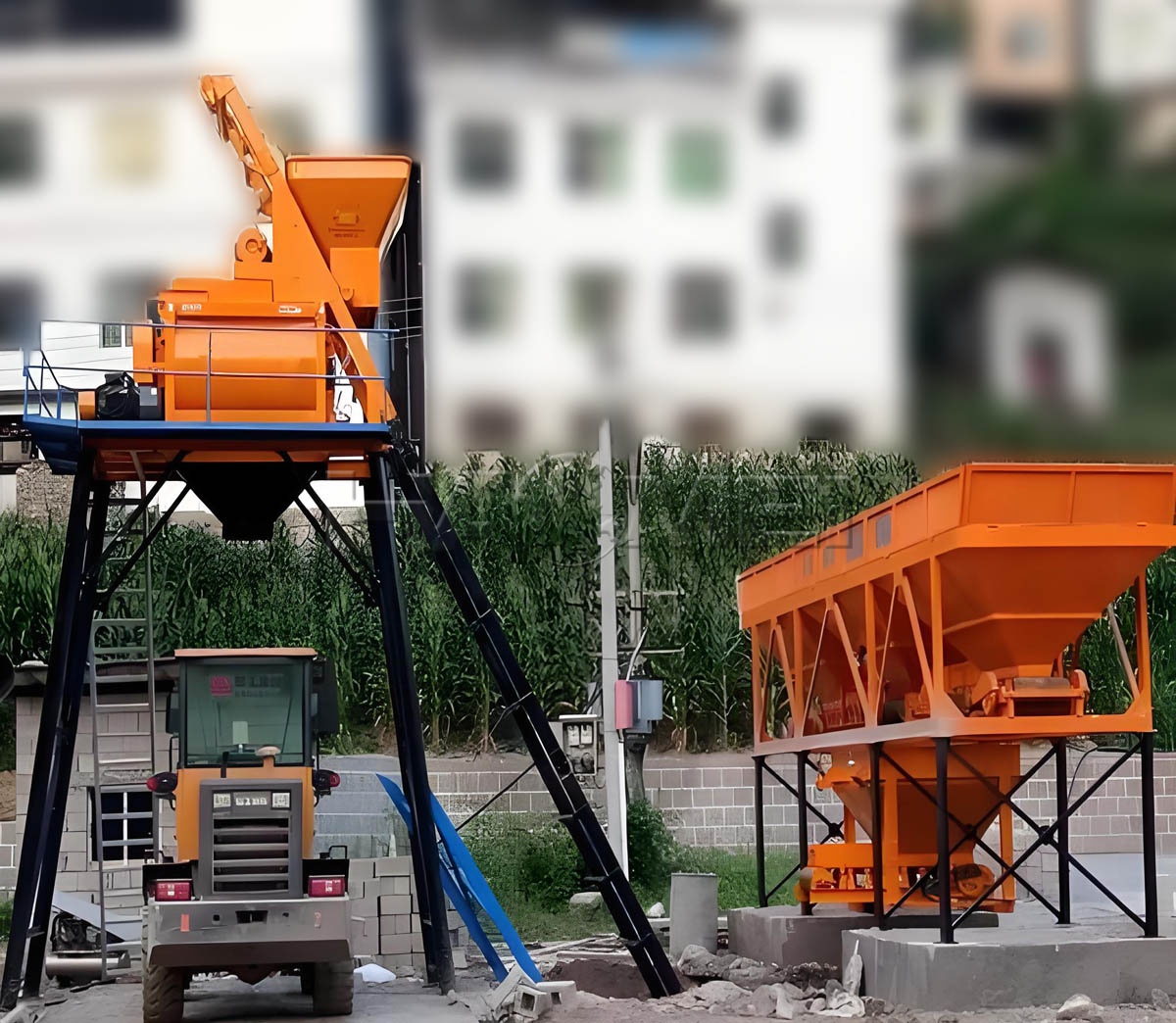

JS Series Concrete Mixer With PLD Batching Machine

1. Why this combination is widely specified on jobsites

In many project environments, contractors need consistent concrete quality without the footprint, investment, or logistics of a full-scale batching plant. A JS series concrete mixer with a PLD batching machine is commonly selected for:

On-site production where ready-mix supply is limited or delivery windows are uncertain.

Small to medium foundations, precast yards, rural infrastructure, and municipal works requiring stable batching accuracy and repeatable mixes.

Frequent mix grade changes (e.g., different strength classes or slump targets) where controlled dosing reduces variability.

From a manufacturing perspective, this set is essentially a compact concrete batching system: the PLD unit performs aggregate storage, weighing, and feeding, while the JS mixer provides forced mixing for uniformity.

2. System composition and working principle

A typical configuration includes:

PLD batching machine: multi-bin aggregate storage, weighing hopper, and belt or skip feeding.

JS series twin-shaft forced mixer: mixing drum, twin shafts with mixing arms, liners, discharge gate, and drive system.

Cement and water dosing (optional): cement silo with screw conveyor, water tank/pump, and additive dosing as required.

Electrical control system: manual or semi-automatic control for sequencing, alarms, and interlocks.

2.1 How the PLD batching machine doses aggregates

The PLD batching machine typically uses load cells to weigh sand and stone by recipe. Aggregates are discharged from bins into a weighing hopper, then transferred to the mixer via belt conveyor or skip. This process improves:

Batch-to-batch consistency compared with volume-based loading.

Material utilization by reducing overfeeding.

2.2 How the JS twin-shaft forced mixer achieves uniform mixing

JS series mixers use two counter-rotating shafts equipped with mixing arms and blades. The forced mixing action increases particle dispersion and helps achieve consistent coating of aggregates with cement paste, especially for:

Low to medium slump mixes

Mixes containing crushed aggregates

Mixes requiring tighter uniformity control

For detailed model selection, the Concrete Mixer range typically pairs with PLD units based on required output, aggregate bin capacity, and site material handling.

3. Typical configuration options (selection logic)

Actual configuration depends on site conditions, raw material storage, and concrete output targets. Common options include:

PLD bin quantity: 2-bin or 3-bin aggregate batching, aligned with sand/stone grading and stock management.

Feeding type: belt feeding for smoother transfer; skip feeding for compact footprint.

Control mode: basic manual control for simple mixes; semi-automatic control for recipe storage and faster changeover.

Wear package: liner plates and mixing blades selected according to aggregate abrasiveness and production intensity.

Dust management interfaces: reserved ports for dust collection and sealed transfer points when cement handling is added.

3.1 Example pairing guidance (engineering-oriented)

The table below summarizes common pairing logic used in equipment planning. Specific selection should be confirmed against local material characteristics, batching accuracy requirements, and production scheduling.

| Project requirement | Recommended PLD features | Recommended JS mixer considerations |

|---|---|---|

| Limited site space | Skip feeding, compact frame | Smaller footprint models, convenient maintenance access |

| Higher batching stability | Load-cell weighing, stable hopper discharge | Forced mixing with reliable discharge gate sealing |

| Multiple aggregate types | 3-bin or more bins | Adequate mixing capacity margin for recipe switching |

| Abrasive aggregates | Reinforced liners at transfer points | Wear-resistant liners and blade material options |

| Faster daily output | Belt feeding, quick discharge design | Higher capacity model and robust drivetrain |

4. Core components that affect reliability and maintenance

From manufacturing and field feedback, the following design points strongly influence uptime:

4.1 Mixer wear system

Mixing blades, arms, and liner plates are wear parts. Their service life depends on aggregate hardness, grading, and mixing time. A maintainable design focuses on:

Accessible inspection openings

Standardized fasteners for quick replacement

Stable shaft-end sealing to protect bearings from slurry ingress

4.2 Weighing accuracy and signal stability in PLD batching

Weighing stability is influenced by:

Load cell installation rigidity and anti-vibration measures

Electrical shielding and grounding quality

Hopper discharge smoothness (reducing residual material impact)

4.3 Discharge cleanliness and material carryover

Material carryover can affect mix consistency between batches. Practical measures include:

Correct discharge gate adjustment

Proper chute angles and anti-adhesion lining options

Routine cleaning procedures matched to cement type and admixtures

5. Engineering application scenarios

A JS series concrete mixer with PLD batching machine is commonly deployed in:

Housing and small commercial projects: foundations, slabs, beams, and site hardening.

Road and bridge auxiliary works: drainage structures, barriers, small culverts, and repairs.

Precast elements (small yard): blocks, curbstones, and simple precast components where batch consistency is required.

Remote sites: projects with limited ready-mix access, where on-site batching reduces dependency on haul distance.

When higher output or automated cement dosing is required, the mixer model selection becomes critical; for example, the JS1000 Concrete Mixer is often specified where a balance of capacity and transportability is needed.

6. Industry trends influencing equipment selection

Current project management and compliance requirements are shaping how compact batching systems are configured:

More attention to mix traceability: increased adoption of control systems that store recipes and batch records.

Maintenance-friendly structures: designs emphasizing faster wear-part replacement and safer access.

Modular upgrades: sites often start with aggregate batching + mixer, then add cement silo, screw conveyor, water and admixture dosing as production becomes stable.

7. Practical commissioning checklist (site-oriented)

The following table outlines common commissioning checkpoints used during installation and startup.

| Category | Check item | Purpose |

|---|---|---|

| Foundation & leveling | Equipment base level, anchor integrity | Reduces vibration and improves weighing stability |

| Electrical | Grounding, phase sequence, emergency stop | Ensures safety and prevents drive issues |

| Weighing | Load cell zeroing, calibration verification | Improves batching consistency |

| Material flow | Hopper discharge, belt tracking/skip alignment | Prevents spillage and material residual |

| Mixer | Shaft rotation direction, lubrication, gate sealing | Protects drivetrain and ensures clean discharge |

| Trial batching | Moisture adjustment and test batches | Verifies consistency under real materials |

8. Summary

A JS series concrete mixer with PLD batching machine forms a practical and engineering-focused solution for on-site concrete production. By combining aggregate weighing and controlled transfer with twin-shaft forced mixing, the system supports repeatable batching, adaptable configurations, and stable operation across a range of jobsite applications. Proper model pairing, wear-part planning, and commissioning practices remain key to achieving consistent production quality and long-term reliability.